Products

Contact us

Address: East Development Zone, Longmen Street, Pingyuan County, Dezhou City

Telephone: 0534-2728298/4251889

Website: http://www.dzddjx.com

Chinese domain name: Dadong Machinery. China / Spiral Duct Machine. China

Mailbox: dzddjx@126.com

Riveting press without rivet

Equipment parameter

Riveting length: one-way 400mm two-way 800mm

Thickness range: 0.3-1.2mm

Power system: gas-liquid booster cylinder, pressure 0.4-0.8Kp, hydraulic maximum 5000Kg

Molding head mold: steel

Total weight: 220 kg

Equipment dimensions: length 800mm, width 700mm, height 1800mm

Total power of the equipment: less than 100W

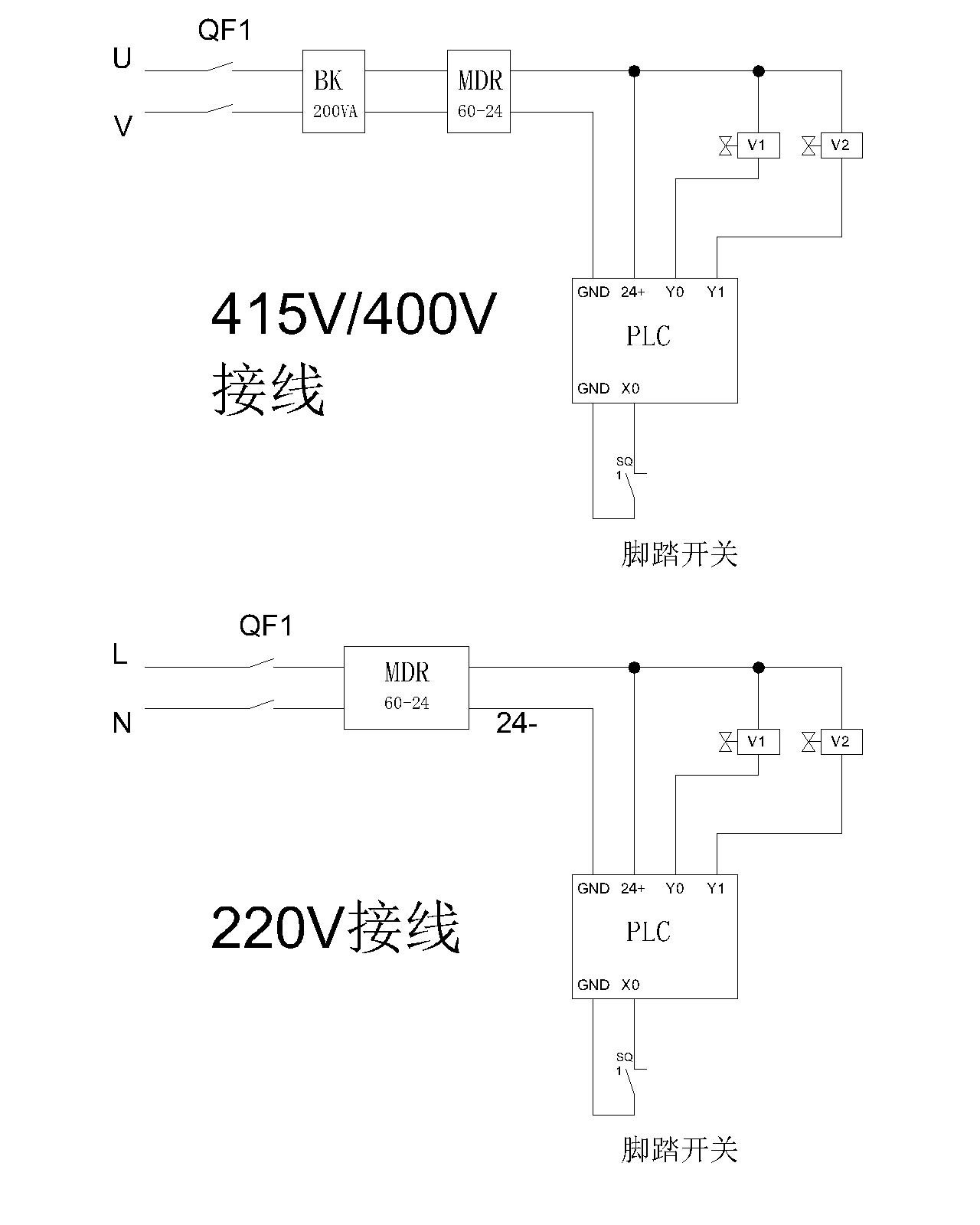

Power supply: 220V/50Hz/2Ph (101fire) 415V, 400V/50-60Hz/2Ph(dual live wire)

Controller: PLC

Mould: five sets of 0.3 0.4 mm, 0.5 0.6 mm, 0.7 0.8 mm, 0.9 1.0 mm, 1.1 1.2 mm.

Matters needing attention

Check whether the gas hydraulic booster cylinder oil level is within the liquid level range, too low to ask for hydraulic oil.

Check whether the air pressure is between 0.3 and 0.7, too low or too high, please adjust the air source.

Check whether the cables are correctly connected.

After checking the ventilation of the equipment, the punch is raised, otherwise it indicates that the equipment is abnormal.

Check if the punches are concentric.

Do not place any part of your body under the punch when working.

Equipment element

- Gas-liquid booster cylinder MPT80*50*10-5T

- Control transformer BK-200VA (选配)

- Circuit breaker NXB-63/D10

- Switching power supply MDR-60-24

- PLC PZ-20MT-2PG

- Air source treatment AC3010-03

- Pneumatic solenoid valve 4V210-08 DC24V

- Laser locator

Preliminary preparation

1,Connect 220V 50Hz to the mains or use any 380V phase + neutral line

415V 60Hz 400V 60Hz Use any 415V/400V two-phase live wire

2, access the air source, pressure 0.3-0.7Mp

3. Assemble the mold. (See Appendix 1 for details)

3. Confirm the relevant contents of precautions.

Trial processing

Adjust the center of the laser positioner in the punch position to facilitate positioning during processing.

Replace with a suitable mold according to the nameplate. (Mold selection error, will lead to the product bite is not tight or the plate is pierced)

Adjust the position of the punch to ensure that the upper and lower die are concentric. (The punch can be pulled down manually after the air is cut off, and automatically withdrawn after ventilation)

Put the plate in the right position, step on the foot switch once, and the punch will automatically process down and spring back. (When the bite force of the processing thick plate is insufficient, it can also actively step on the foot switch to extend the bite time)

Adjust the nut above the punch to change the punching distance. The biting force can not only meet the requirements of use, but also facilitate the locking nut after demoulding.

Appendix 1

According to the product, select the appropriate mold according to the nameplate.

Remove the lower die sleeve, install the lower die, lock the top wire. (Lower die for tight fitting, can be driven into copper rod or rubber mallet)

Remove upper die sleeve, insert upper die, lock upper die sleeve to piston extension rod.

Install the piston extension rod to the piston rod, adjust the upper and lower die spacing to 45-50mm, and lock the lock mother. Manually pull down the piston rod and check whether the upper and lower dies are concentric. Post-concentric ventilation.

When disassembling the mold, press the reverse operation. When the lower die is not easy to disassemble, the hard object can be punched upward at the bottom hole.

Appendix 2

MESSAGES

If You Have Any Questions, Please Consult! Thanks For Your Message.

MESSAGES

Address: East Development Zone, Longmen Street, Pingyuan County, Dezhou City

Telephone: 0534-2728298/4251889

13305349821

Website: http://www.dzddjx.com

Chinese domain name: Dadong Machinery. China / Spiral Duct Machine. China

Mailbox: dzddjx@126.com

Mobile Access

COPYRIGHT © 2021 Dezhou Dadong Machinery Co.,LTD. 鲁ICP备13020025号 Powered by www.300.cn